Prototypes

Recommended Products

Contact Us

Contact Person: Cindy Zhu

TEL:+86 13418453374

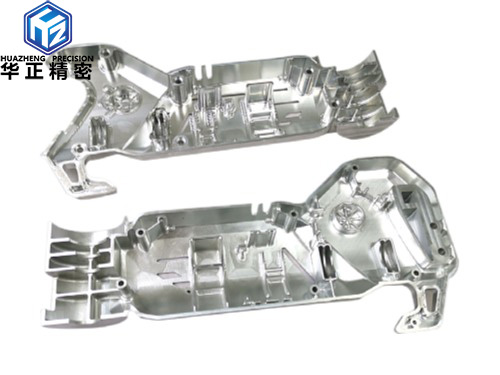

Robot turning arm aluminum alloy processing

基本參數(shù):

樣件名稱:鋁合金汽車配件手板模型加工廠家

材質(zhì):金屬、鋁合金

加工方式:CNC加工

顏色:無色

尺寸:50mm*220mm

精度:0.01mm

Manufacturing Process of Aluminum Alloy Handplate

01/

Programming

Programmers use programming software to set the path and program of products according to the drawing requirements given by customers.

/02

CNC Machining

After the program is written, the programmer will hand the program sheet to the operator. The CNC operator will copy the program to be used for processing the workpiece into the CNC machining center, compare the props to be used for the program sheet, equip the material, and process on the machine.

03/

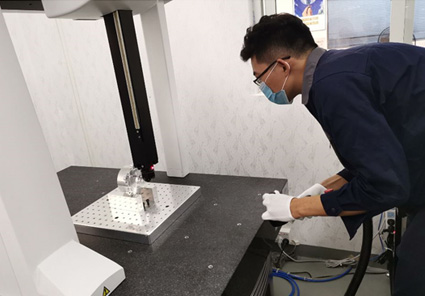

QC inspection

The quality department checks the dimensions of the drawings.

/04

Manual handling

CNC processing gongs give the rudiment of products, the surface will leave a lot of knife marks, burrs, so it is necessary to use sandpaper to remove the edges, polish, polish with polishing paste, so that the product surface is smoother, reduce the roughness of the product.

05/

Surface treatment

In order to achieve the appearance and function required by customers'drawings, spray painting, silk printing, oxidation, radium carving, electroplating and other processes are also carried out.

/06

All qc inspection

In order to reassure customers, 100% of the products are fully inspected. For high-precision parts, 2.5 or three-dimensional inspection is used, and qualified quality reports are provided.

07/

Packaged goods

Air express delivery, next day delivery.

CNC Machining Advantages

The number of tooling is greatly reduced, and complex tooling is no longer needed to process parts with complex shapes. If you want to change the shape and size of the parts, you don't need to trouble to modify the parts processing procedures, which is suitable for the development and modification of new products.

The processing quality is stable, the processing precision is high, and the repetition precision is high.

In the case of multi-variety and small batch production, the production efficiency is high, the time of production preparation, machine tool adjustment and process inspection can be reduced, and the cutting time can be reduced by using the best cutting quantity.

It can process complex profiles which are difficult to be machined by conventional methods, and even some parts which can not be observed.

Our Strength

CNC Equipment

Programme Discussions

CNC Processing

Electroplating Treatment

Three-dimensional Testing Equipment (CMM)

2.5-dimensional Detection Equipment

Related Information

Corporate Welfare - Quarterly Employee Birthday Party

2022-06-18CNC machining aluminum alloy

2021-10-14What types of common five-axis milling machining centers are there?

2021-10-30What are the basic components of a CNC machining center?

2022-01-20Process cost control of CNC machining

2021-12-04Process cost control of CNC machining

2021-12-01The company organizes employee travel

2021-12-18Huazheng Precision has started!

2022-02-09Several key points affecting the machining accuracy of precision parts

2022-08-20Precision non-standard precision non-standard parts processing process

2022-08-23Japanese customer visit

2018-11-14What are the types of CNC precision parts processing?

2022-07-14How to make five-axis CNC machining simple and convenient

2021-12-20Development of five-axis machining technology

2021-12-20Why is it difficult for factories to recruit and retain people?

2021-12-31Features of zinc alloy lamps

2022-01-06Anchor point Huazheng precision anchor point aluminum alloy machining/precision machining/CNC CNC machining manufacturer

2021-10-16Analysis of Influence of Machining Allowance on Part Accuracy

2022-08-27CNC machining of new energy vehicle parts

2022-09-17Shenzhen strength CNC processing factory

2021-12-01